Clayworks completes EPD

CLAYWORKS ENVIRONMENTAL PRODUCT DECLARATION

Clayworks is the first Clay Plaster manufacturing company in the world to complete an Environmental Product Declaration.

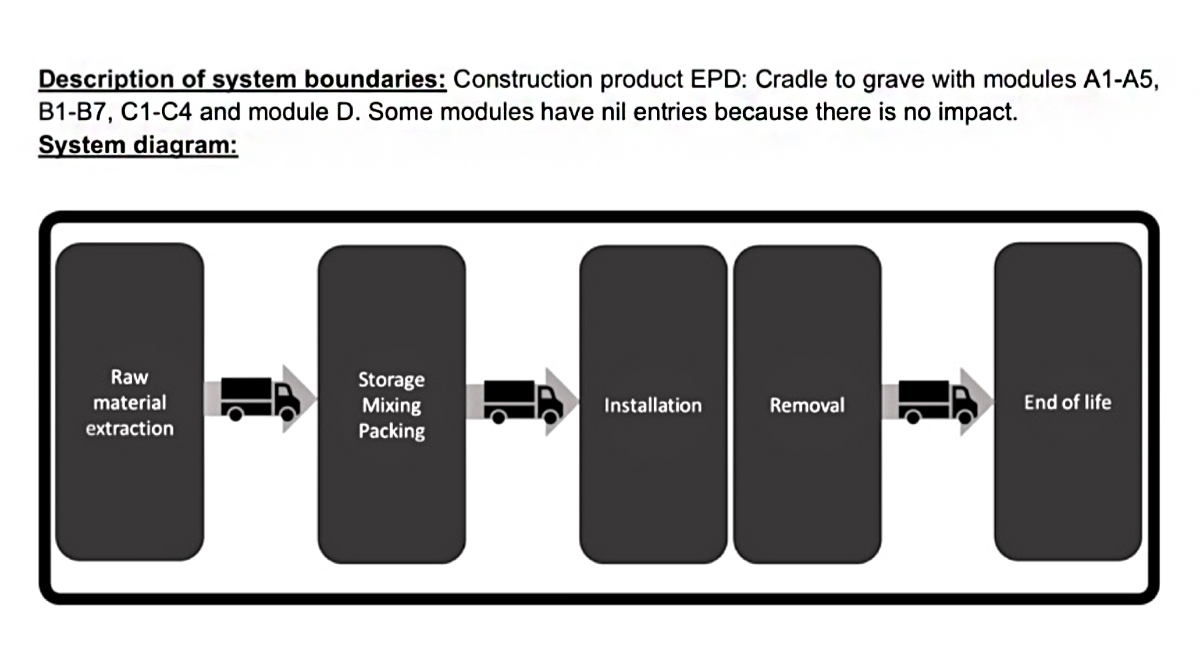

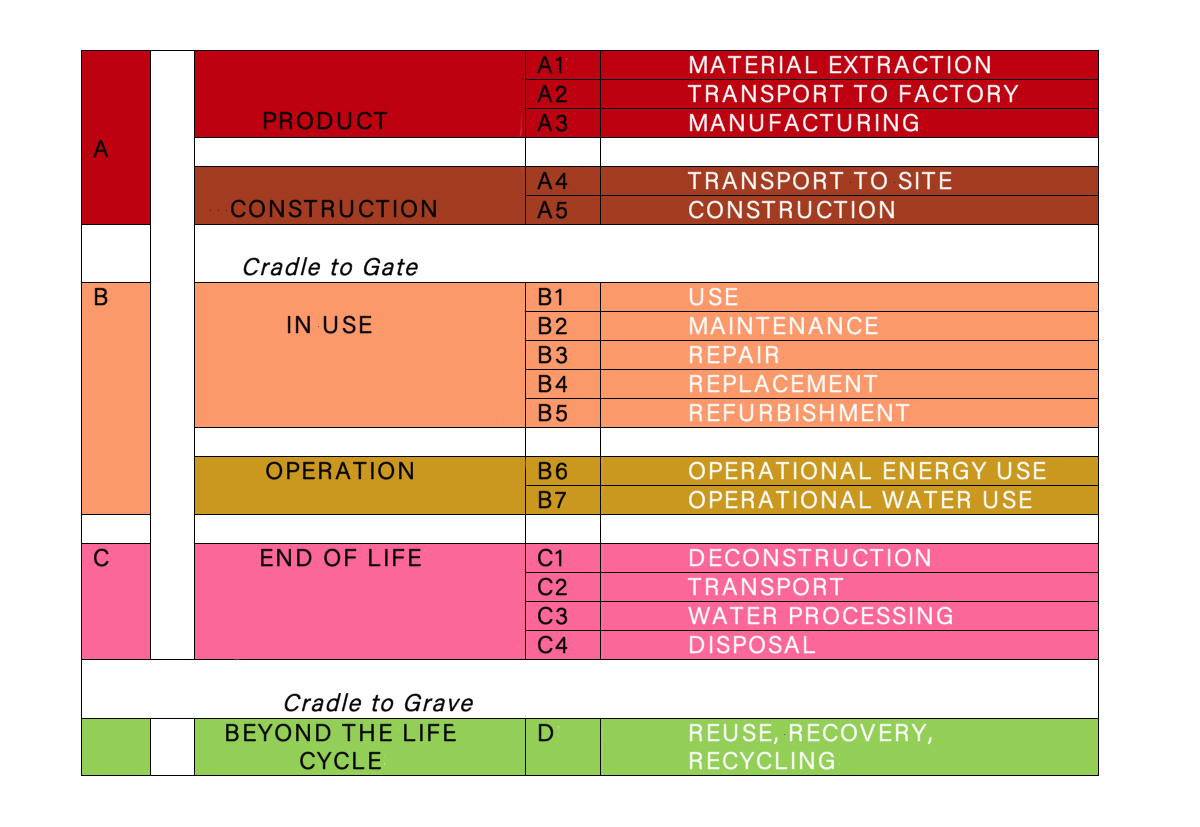

An EPD is the global standard that quantifies environmental information on the life cycle of a product. It measures all of the embedded carbon in a product from when the raw materials are originally sourced through to what happens at the end of the life of that material. The declaration, completed and verified by specialist 3rd parties, enables comparisons between products that fulfil the same function so that materials specifiers can make more informed choices about the sustainability of the projects they design.

Architects around the world are under increasing pressure to model and measure the embodied carbon of the buildings they design.

It has always been known that clay plasters are the most sustainable of wall finishes, but to date all measurements of embodied carbon (EC) in these materials have been based upon assumptions and very basic, generic calculations. They have also only measured the EC in the product from when it is extracted to before it leaves the factory. The Clayworks Declaration measures the EC throughout the clay plaster’s life until it is, hopefully, composted.

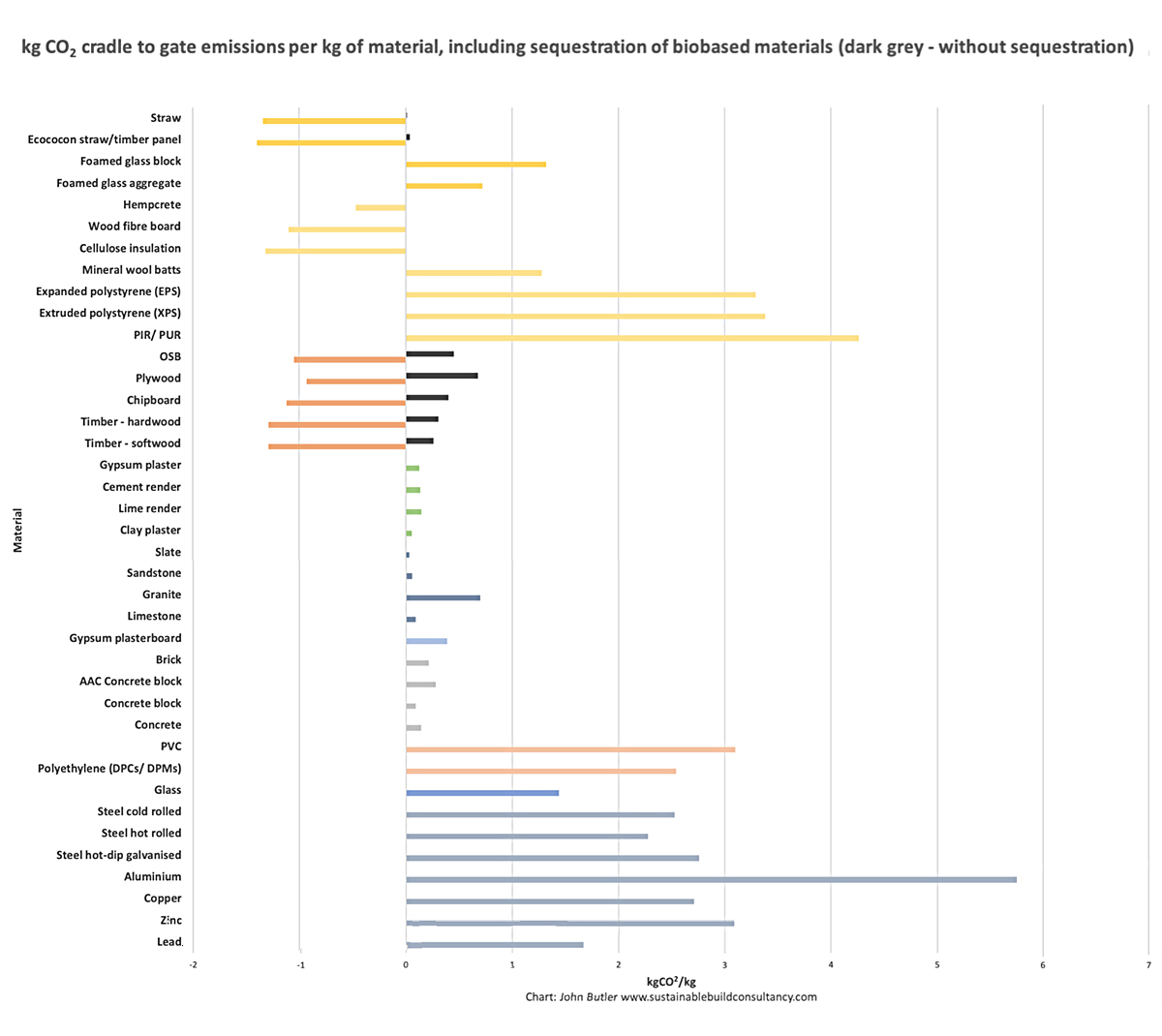

Certified Passive House consultant John Butler has incorporated the Clayworks data into his graph comparing the embodied carbon of most building materials.

The data in John’s table refers to ‘cradle to gate’ carbon emissions – those caused by extraction (the cradle), transport and processing of raw materials, and manufacture of the product, up to the point it leaves the factory (the gate). John states that emissions after that point are ignored, which gives a slightly skewed impression since our data includes the additional emissions of transporting to site, use and disposal. Despite this, Clayworks Clay Plasters compare exceptionally well.

Chart by John Butler.

WHY IS EMBODIED CARBON IMPORTANT ?

‘What matters is every kilo of carbon in every building starting right now’.

Lloyd Alter, Editor of Treehugger.

In the next 30 years, the global building stock is expected almost to double. It already accounts for around 36 – 39% of total international energy use, placing a significant burden on the natural environment. The environmental loadings associated with the material production of all components of a building can be greater than those related to the operation of a facility.

The World Green Building Council in 2019 set forth the need for urgent action to reduce building emissions, with their report Bringing Embodied Carbon Upfront.

This report issued a bold new vision by the WGBC:

- By 2030, all new buildings, infrastructure and renovations will have at least 40% less embodied carbon with significant upfront carbon reduction, and all new buildings are net-zero operational carbon.

- By 2050, new buildings, infrastructure and renovations will have net-zero embodied carbon, and all facilities, including existing buildings, must be net-zero operational carbon.

In the UK, the Royal Institute of British Architects (RIBA) has set stringent targets for embodied carbon reduction, along with operational energy and water use reduction. They are calling for targeting net-zero whole life carbon for new and retrofitted buildings by 2030 using whole life carbon analysis and Circular Economy strategies. The RIBA Sustainable Outcomes strategy prioritises a fabric first principle for building form over the use of mechanical interventions where possible.

As a consequence of this heightened awareness of EC, a new generation of architects is asking tougher questions about the materials in construction. Several leading architects are even calling for embodied carbon targets to be conditional for planning permission.

MATERIALS INFLUENCE ENVIRONMENTAL PERFORMANCE

Materials are the principal source of embodied carbon emissions from buildings and infrastructure.

Those responsible for the planning, design, retrofit, construction, and ongoing management of our buildings face a plethora of decisions about the impact of buildings. One of the most crucial decisions is the selection of construction materials.

Many materials can require a considerable quantity of natural resources and result in a large amount of waste, pollution and carbon emissions in their extraction, refinement and processing as well as their ongoing maintenance.

Although a large amount of info, tools and data on material performance exists, these are often inaccessible, overly complex or costly. Understanding the dynamic interactions between the environmental effects of materials and the operational performance of a building is complicated and seldom understood.

HELPING ARCHITECTS

One of the biggest issues for architects is the challenge of having access to all of the information and data they need to make informed decisions about modelling the carbon footprint of the buildings they design. Designers and builders can completely transform the carbon footprint of their buildings through carbon smart material choices. Any time the manufacturing industry can simplify things for architects it helps. Easy to use – and 3rd party verified – information and data is crucial and this is what the EPD provides

Decisions involving the appropriate selection of materials involve several aspects: the aesthetics, the actual performance of the given material within a specific context and, increasingly, the materials effect on the environment.

‘A building will have emitted 100% of its embodied carbon the day it is built. If every designer could change just a percentage of the materials in a design project it would be a step in the right direction.’

COMPARING MATERIALS

As mentioned above, extreme caution is required when comparing materials as the declared EC for many materials is only for Cradle to Gate while for others, such as Clayworks, it is Cradle to Grave.

Other variables include differing densities of materials and the frequency of replacement. Clay plasters can last for 100s of years and being naturally pigmented, they will never require painting. Butler explains more about comparing materials here.

The end of life phase is extremely important to consider. The more materials can be re-used or recycled, the lower the life-cycle embodied carbon will be. One reason Clayworks materials are so sustainable is because they can be wholly composted, a process enabled by using them on natural, compostable backing boards.

RIBA SUSTAINABLE OUTCOMES GUIDELINE SUMMARY

· Review the embodied energy and carbon of materials and construction processes in the context of the buildings lifespan and operational strategy

· Minimise high embodied energy materials. Prioritise low carbon and recycled materials.

· Use embodied energy and carbon assessment to test relative impacts of design options as part of whole life costs.

· Prioritise low carbon materials.

· Avoid inefficient/wasteful use of materials. Design out waste where possible.

STEPS TO MINIMISE CARBON

· Reduce the need for materials and energy – keep it simple with a fabric first approach.

· Choose Materials and energy solutions with a minimum climate impact.

· Choose materials that enhance the performance of a building thereby reducing the need for mechanical intervention. E.g. clay will naturally help thermal variation, insulation, humidity control and acoustics.

· Carbon emissions also include those due to the maintenance, repair and replacement as well as final demolition and disposal.

· Using informed modelling, architects can control material selection and costs while ensuring the building contributes to low emissions from a life cycle perspective.

EDP AND BUILDING DESIGN

Using the information in an LCA and EPD is complicated. There are many variables for modelling buildings and it is advisable that a specialist be involved. Passive House Consultant John Butler exposes many of the things to think about and does an excellent overview of how modelling might work in a Passive House.

Engaging in EC modelling should be done at a very early stage and there are several tools to help architects with this including:

· Open LCA

· ICE

· HBERT

· EC3

· Rapiere

EPDS AND OTHER BUILDING STANDARDS

EPDs are recognised and rewarded by the following:

· BREEAM

· LEED

· Living Building Challenge