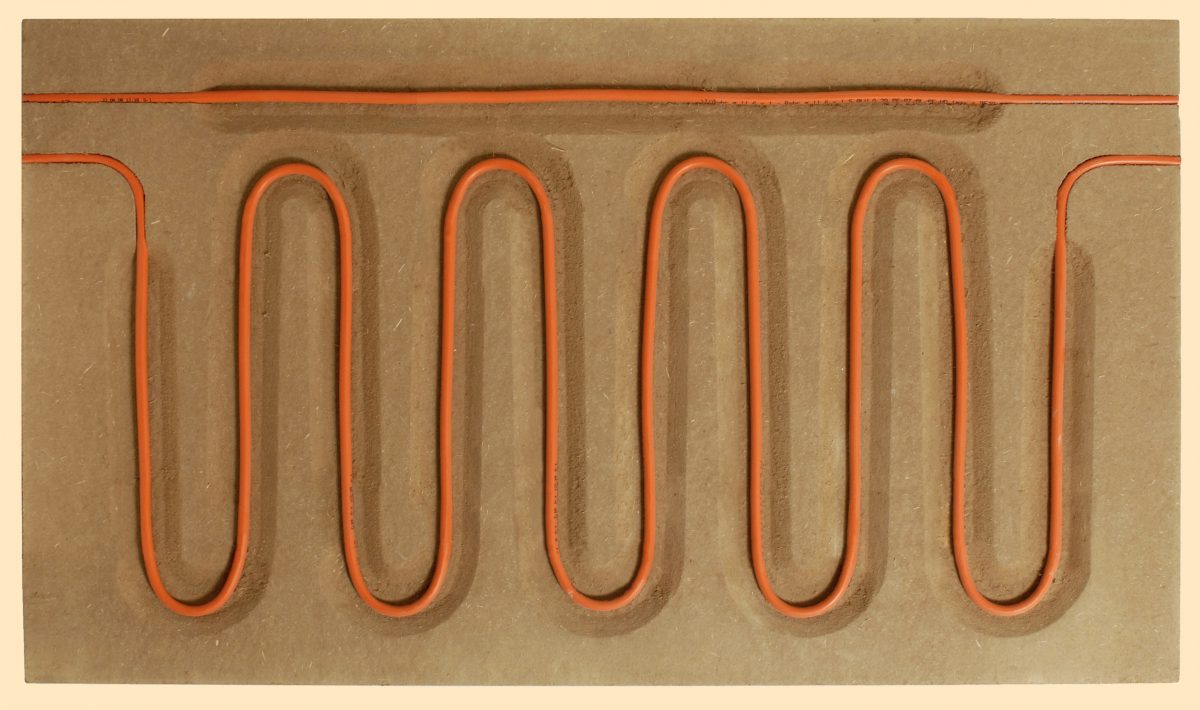

Clayworks wall & ceiling heating system

Clayworks wall & ceiling heating system at Open House 2020

Pioneering clean clay ‘technology’ can help house builders and retrofitters meet the challenge of delivering low cost, low carbon heating.

Clay panel, in-wall and in-ceiling heating systems with clay plaster finishes will be presented by Clayworks at Open House on 22 and 23 September, demonstrating how clay can be truly problem solving and rich in value.

The retrofit of a 150 year terraced house in London that was, until recently, used as a squat was undertaken by London architect Silke Stevens who, upon stripping the house, exposed stunning clay plaster partitions, brick fireplaces and pine floorboards that gave a warm and authentic feel to the building, and which she was keen to retain. Moreover, not cluttered by radiators. Underfloor heating was impractical due to the excellent condition of the original floorboards, and hence she sought a practical, and sustainable, alternative.

Heating embedded in natural clay panels: the future technology for smart homes

And so Stevens specified a clay panel heating system because of its invisibility, sustainability, and low running costs.

The panels were installed underneath the Victorian ceiling joists throughout the house except for the bathrooms where they were used on the walls due to limited ceiling space. They were connected to a conventional manifold and boiler, and tested under substantial pressure to ensure no leaks.

Clayworks Clay Plaster was specified to cover all of the walls and finishes, completing an entire clay wall system that demonstrates the potential for delivering lower carbon heating in new build and retrofit buildings.

The main question is always, how is it possible and even desirable to have the heat source located at high level?

The answer is that the system works very much by heating up the clay first which then radiates healthy warmth like the sun or a clay oven. Rather than heating up the air around you to keep you warm, the infrared heat can be felt nearly instantly on the surface of your skin. It is very gentle, running at much lower temperatures than radiators and connects to the same boiler/manifold/tank like underfloor heating.’

A new, low carbon, clay panel wall heating system

Drying times can be an issue when using clay in modern construction, especially in winter, but the use of pre-dried clay panels can reduced the drying time considerably, and open up new opportunities for the use of clay in larger projects and tighter time frames. The finish plaster applied dries quickly within 2-3 days and fits into any construction process.

Due to the remarkable qualities of clay, the system has many health benefits, too. It reduces dust and allergens in the air, balances humidity and absorbs odours. The panels are 99% recyclable and require very little energy during production as the wet clay is applied to either side of a wood fibreboard and dried at low temperatures. The weight of the clay combined with the wood fibre make them excellent noise insulation panels too. All of the above combined with the traditional use of clay as a natural surface material also means they are perfect for restoring historic buildings.’

This is the first project to use heated clay panels in the UK, and the first to complete a heated wall system entirely of clay using traditional materials with applied technology and innovation that demonstrates a new construction methodology.

It is proof that we absolutely can have buildings that are both energy efficient and healthy for both people and planet. That simple, natural materials, including breathtakingly beautiful wall finishes that require no firing and minimal processing, can be part of a more holistic approach of integrating sustainability and health into the very fabric of the building rather than bolting it on afterward.

More people are realising that clay materials can be a vital tool in tackling the construction, health and environmental challenges of our time and this house demonstrates how readily abundant natural materials can be a major part of the solution.

Contractors: Lamabuild