Data & Performance

1. OUR PRODUCTS

Clayworks Clay plasters are unique blends of unfired clays mixed with minerals and pigments to provide a healthy, breathable finish for internal walls and ceilings.*

Manufactured in Cornwall, UK from abundant raw materials, they are amongst the most sustainable wall finishes available. With low VOCs (harmful chemicals released during and after application) and no synthetics they are healthy for the planet, the building fabric and the occupants.

* For a 3rd party overview of clay plasters see Clay Plasters, by Neil May, Natural Building Technologies, April 2005

2. OUR RANGE OF FINISHES: CLASSIC & CUSTOM

Smooth & Tonal finishes

These are our smoothest finishes, created with the finest raw materials, and come with the option of a micaceous additive – Mica – which produces a subtle iridescent radiance in direct light.

Demi Rustic finishes

A clay plaster with slightly larger aggregate grain sizes, thus providing a subtly courser finish and a slightly thicker application in one coat. The health and performance benefits are enhanced due to the additional material in use.

Rustic finishes

A single coat, robust and coarser finish ideally suited for artisanal finishes such as two-tone carving and relief work.

4. PRODUCT DATA

Standard shipment quantity 25kg bags.

Coverage (per 25kg bag):

Smooth Finish: 7-8m² @ 2mm thickness.

Demi-Rustic Finish: 2.7m² @ 5mm thickness.

Rustic: 1.25m² @ 10mm thickness.

Heavy Texture Rustic: 1.25 m² @ 10 mm thickness.

Base Coat: 1.25 m² @ 10mm thickness.

Loose weight: 25 kg dry powder in brown paper bags.

Volume with water added (approx. 10 litres) to 25kg dry powder: Approximately 20 litres.

5. WALL SURFACE PREPARATION

Suitable for use on most stable internal surfaces when properly prepared with Clayworks Primer. Such surfaces include plasterboard or gypsum plaster surfaces. Rough surfaces require a straightening coat of lime or clay. Not to be used in areas in direct contact with liquid moisture, excessively damp areas or the elements, although can be used in areas of high humidity, such as bathrooms and kitchens.

Not suitable for floors or stair treads.

Clayworks Clay Plasters are suited to historic and eco-walling substrates such as cob, lime, hemp and strawbale due to their breathability and elasticity.

For a sustainable outcome, we recommend that Clayworks Clay Plasters are applied to a wholly compostable backing board so that the entire wall system may avoid landfill at end of life, contributing to the Circular Economy.

6. FIRE: NON COMBUSTIBLE BUILDING MATERIALS

Tested and Classified by BRE in accordance with BS476, part 7, 1997, achieved Class 1. Non Combustible, with no spread of flames.

Euroclass A1 Fire Rating to EN13501 and EN15824 international standards. Certificates available upon request.

7. BREATHABILITY: MOISTURE. HEALTH AND SAFETY ABSORPTION VALUE

1.28 for Smooth and 1.4 for Rustic [calculated by moisture change (g/m²) divided by relative humidity] where buffering was tested to be 9x that of painted plasterboard. (University of Bath figures).

8. HEALTH & SAFETY

Non caustic: can be handled without gloves. Wear a dust mask when mixing dry powder.

9. APPLICATION

Applied in the conventional manner with a hawk and laying on trowel. Can also be applied with a spray machine.

Application is similar to gypsum with the exception of the finishing process. A smooth finish is preferred for durability and cleaning. This is achieved by hard polishing with a plastic trowel or a Japanese Trowel. However, an open grained, more textured finish can be achieved using a damp sponge to lose trowel marks. This is often a more suitable finishing approach for undulating surfaces. For further detail please see our Application Guidance Notes.

10. FINISHING

Clayworks Clay Plasters have natural variations in their colours and textures – this is to be expected due to the use of only natural materials and pigments. The colour will not be flat like a paint but instead have a tonal variation that creates slight ‘movement’ in the wall. The texture also has natural variation. For the Smooth and Tonal Finishes it wants to be relatively smooth to the touch when a hand or finger is dragged across the surface area. The finish is not comparable to the texture of a gypsum plaster wall as it will have more variation to a gypsum wall – this is what creates the unique aesthetic.

Best finished with Clayworks protective glaze for maximum damage resistance. Can be painted with micro-porous paint or pigmented protective glaze for an interesting decorative effect.

11. COLOURS

88 Standard Colours and endless Custom Colours and aesthetic effects. Our colours are created with pigments throughout the material and hence the clay plasters will never require painting. This means significant savings in time, materials and also carbon.

12. DRYING TIMES

Dependent on ambient conditions in the room, and rates of absorption from the background material. In ideal conditions, the plaster should be fully dry within 24 hours, but can take up to 48 hours. Good air circulation is encouraged during and after application.

Low, even heat can be used in cold conditions, but must be used with caution as it can cause hairline cracks in the plaster if it dries too quickly.

13. WORKING CONDITIONS

Application should not proceed when temperatures fall below 5 degrees centigrade or rise above 30 degrees centigrade.

14. CLEANING

Wipe gently with a soft, damp sponge, if it has been finished previously with Clayworks protective glaze. On textured surfaces, such as the Arakabe or Sculpted, cleaning should be carried out with due care and attention avoiding rough treatment of the surface.

15. HANGING PICTURES

Observe the same protocol as for conventional plaster using picture hooks or screws.

16. PHYSICAL PROPERTIES & COVERAGE

Densities

Loose, dried Clayworks clay plasters as delivered in 25kg bags.

| low g/L | high g/L | ||||

| Smooth powder | 1137.581 | 1573.407 | |||

| Demi Rustic powder | 1132.041 | 1506.464 | |||

| Rustic powder | 1240.536 | 1581.256 |

Applied Clayworks clay plasters

| g/l | kg/m3 | Thickness (mm) | kg/ m2 | ||||||

| Smooth applied plaster | 1270 | 1270 | 2mm | 2.5 | |||||

| Demi Rustic applied plaster | 1682 | 1682 | 6mm | 10.1 | |||||

| Rustic applied plaster | 1536 | 1536 | 10mm | 15.4 |

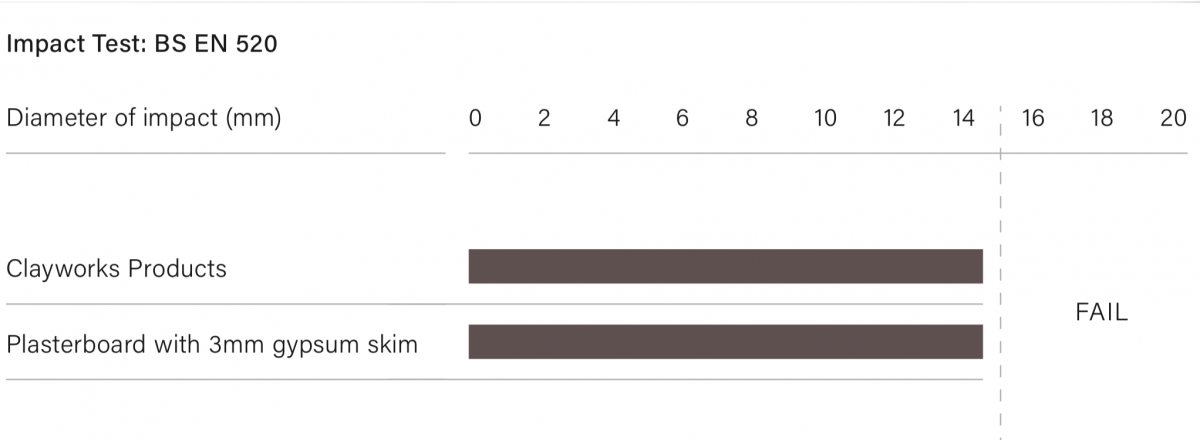

Impact

Smooth and Tonal Finish:BS EN 520 – Impact Diameter < 15mm

Demi-Rustic Finishes:BS EN 520 – Impact Diameter < 15mm

Rustic Finishes: BS EN 520 – Impact Diameter < 15mm

Thermal Conductivity

Smooth and Tonal Finish:0.84 W/mK

Demi-Rustic Finishes:0.97 W/mK

Rustic Finishes: 0.97 W/mK

Moisture Buffer Value

Smooth and Tonal Finish:1.28

Demi-Rustic Finishes:1.4

Rustic Finishes: 1.4

Thickness when applied

Smooth and Tonal Finish:2mm

Demi-Rustic Finishes:5-7mm

Rustic Finishes: 7-15mm (standard is 10mm)

Coverage per 25KG Bag

Smooth and Tonal Finish:7-8sqm

Demi-Rustic Finishes:2.7 m² (at 5mm thick)

Rustic Finishes: 1.25 m² (at 10mm thick)

Embodied Carbon

Extremely low in embodied carbon – 0.1048 – 0.068 kg CO2 e/kg (LCA stages A1 to A3. Full A1 – D assessment is available in our EPD.

Acoustic Absorption Properties

Smooth and Tonal Finish: Noise Reduction Coefficient (NRC): 0.10 NRC:

Sound Absorption Coefficient: 0.090N

Demi-Rustic Finishes: Noise Reduction Coefficient (NRC): 0.10 NRC:

Sound Absorption Coefficient: 0.090N

Rustic Finishes: Noise Reduction Coefficient (NRC): 0.10 NRC:

Sound Absorption Coefficient: 0.090N

Origin: All Finishes: Cornwall, UK

17. MATERIAL PERFORMANCE

Flexibility

Seamless surfaces and flexibility accommodate movement of building elements.

Acoustic Absorption

Noise Reduction Coefficient (NRC): Demi 0.15; Rustic 0.20 (on gypsum board). Smooth is estimated to be 0.10. Clay plasters are a well known acoustic absorber: the thicker the material, the higher the performance benefit. Coefficient tests conducted in accordance with British Standard BS EN ISO 354 available.

Surface Hardness

Surface Hardness is Excellent. As there is currently no standard for testing the performance of clay plasters the impact resistance of Clayworks products was tested to BS EN 520, the standard for gypsum plasterboards. The impact resistance test drops a standard weight and measures the diameter of impact.

Clayworks clay plasters achieved a surface hardness equivalent to Type I (enhanced surface hardness) plasterboard, with an average impact diameter less than 15mm. The performance was identical to gypsum rendered plasterboard tested in parallel.

Clayworks have been used in Nandos restaurants around the world since 2010.

Repairs

Any damage caused to a Clayworks Surface will be inconspicuous due to their through bodied colouring. Chips, divots and scratches can be simply repaired through the addition of a small quantity of colour matched clay plaster, trowelling and reapplication of the protective glaze.

Fundamental Material Safety of Clayworks Clay Plasters

Clayworks Clay Plasters contain no Asbestos, Lead, PCBs or Mercury. They contribute to Toxic Material Reduction targets because they contain no Perfluorinated Compounds (PFCs), no flame retardants or Phthalates (Plasticisers), or Isocyanate based polyurethaneS. Clayworks Clay Plasters contain no synthetic additions and emit extremely low VOCs or formaldehydes.

VOC emissions specifications in LEED EQ credit “Low -Emitting Materials” for LEED projects globally: The requirements of LEEDv4 and LEED v4.1 BETA (February 2021): CDPH-IAQ (California Department of Public Health (CDPH) Standard Method v1.2 – 2017); abd a TVOC below 0.5 mg/m3 in both office and class room.

VOC content specifications in LEED EQ credit “Low-Emitting Materials” for LEED projects globally:

The requirements of LEED v4 and LEED v4.1 BETA (February 2021): South Coast Air Quality Management District (SCAQMD) Rule 1113 (2016) for Trowel Applied Coatings having a VOC content below 50 g/l.

There is evidence to suggest they may proactively mitigate the presence of formaldehydes in a space.

Thermal Properties of Clayworks Clay Plasters

According to research by Tom Morton et al, the physical mass of clay plaster (20.6 kg/m²) is 2.5 times that of gypsum plaster (8kg/m²). According to Borer and Harris (see footnote 14) the denser building materials perform better in storing heat, with dense soil as the best performer in comparison with other building materials such as fired brick, concrete and stone (Borer and Harris, 1998). N.B. Clay Plaster has a density of 1900kg/m³ as opposed to the 1370kg/m³ of the clay plaster in these tests. The thicker the build up, the better the thermal properties of clay. Adding base coats can build up deeper layers of clay. The outcomes are:

• Reduce/replace use of ventilation systems/extractor fans and associated operating, maintenance/repair costs.

• Saving on energy/heating bills through the evening out of temperature swings (see below).

• Savings on resistance to building overheating through thermal mass effect. Even a 15mm plaster coat has significant thermal mass to store heat (see footnote 13) Morton T. et al.

Breathability & Clayworks Clay Plasters

For a comprehensive guide to the Indoor Air Quality benefits of breathable clay plasters see HERE [link to health page]. Other performance outcomes from their hygroscopic properties include:

• Hygroscopic materials contribute to thermal comfort thereby permitting smaller heating systems. The walls will absorb and store heat and moisture, buffering against temperature and humidity fluctuations. Mechanical ventilation systems can be eliminated. (Ruth Busbridge, MSc Jan 2009, footnote 9).

• A porous wall will absorb this moisture and release it when the room is aired during the day, giving a lower average RH. This will reduce the operating time of a dehumidifier or make it unnecessary. (Tim Padfield PhD, footnote 4).

Clayworks and Water

Clayworks Clay plasters are very suitable for bathrooms and kitchens due to their moisture absorbing properties. They have such a strong ability to absorb peaks of air moisture after showers that they clear the air without surface condensation and ‘the effect of the extractor fan was of no statistical significance’ according to Tom Morton.

Clay Plasters are not, however suitable for areas where there is running water such as showers, wet rooms or exteriors for example. If there is a likelihood of fire sprinklers being tested onto walls finished with clay plasters, then we would recommend that our 100% clay plasters are not suitable. We are able to create products that are suitable for wet areas.

Ceilings

Clayworks Clay Plasters are very suitable for ceilings. The Smooth and Tonal Finishes, at 2mm thick do not require a special build up. For Demi Rustic, Rustic or Custom Finishes please contact us to discuss ceiling build up for additional weight.

(1) Materials World, Tom Morton, Jan 2006 http://www.arc-architects.com/downloads/Materials-World-Article-Jan-2006.pdf

(2) https://strawtec.com.au/clay/

(3) http://www.homegrownhome.co.uk/pdfs/Energyassessmentofastrawbalebuilding.pdf

(4) Morton, T et al (2005) Low Cost Earth Brick Construction – 2 Kirk Park, Dalguise: Monitoring & Evaluation. Arc, Chartered Architects 69 Burnside, Auchtermuchty, Fife http://www.arc-architects.com/downloads/Low-Cost-Earth-Masonry-Monitoring-Evaluation-Report-2005.pdf

(5) Borer, P., Harris, C. (1998) The Whole House Book. The Centre for Alternative Technology. Machynlleth, Wales

Disclaimer:

Clayworks Limited accepts no responsibility or liability for any damages or costs of any type arising out of or in any way connected with your use of this web site. Data and information are provided for information purposes only and is not intended for commercial or trading purposes. We have compiled the information with considerable time spent in checking references and authenticity of content. If you feel that any of the information is inaccurate, or misrepresentative, please let us know. Our intent is to genuinely disseminate information that is reasonably felt to be the case.