Sustainability

1. INTRODUCTION

Clayworks was born from a love of nature and belief in natural, sustainable building practices. It was the result of over a decade of building and restoring with natural materials, travelling the world to learn about the traditions of clay as a building material.

The company has always believed in design being holistic and respectful of the needs of people and planet. We understand that buildings are a leading contributor to greenhouse gas emissions and our mission is to create materials that can do less harm, release less carbon and that are healthier.

From our workshop in Cornwall, Clayworks manufacture readily available, affordable and easy to use natural clay plasters for interiors.

2. CLAY PLASTERS

Clayworks clay plasters are unique blends of unfired clays mixed with minerals and natural pigments to provide a healthy, breathable finish for interior walls and ceilings. They are a more sustainable alternative to gypsum plaster and paint, supplied ready to mix with water and be applied with conventional plastering tools and skills.

Clay plasters are natural and non-toxic, with low VOCs emissions and no synthetic, concrete or lime additives. Made from readily available, naturally abundant materials, they require no processing, only blending. During the manufacturing process very little energy is required, no water is used, and there is zero waste produced.

Amongst the most sustainable wall finishes available, clay plasters are recyclable, repairable and compostable. They allow buildings to breathe, attenuate acoustics and help regulate humidity and temperature.

Clayworks clay plasters offer high-performance with low environmental impact.

3. KEY SUSTAINABILITY FACTORS

Clayworks clay plasters are…

Low embodied energy and embodied carbon

Non-toxic, inert and releases low VOCs

Long lasting, with a 60 year lifespan

Repairable

Compostable

Breathable

Passive regulator of interior humidity

Available with an EPD

Produced in the UK

4. EMBODIED CARBON

What is embodied carbon?

The embodied carbon of a material product, also know as its ‘carbon footprint’, is the amount of greenhouse gasses emitted as a consequence of producing, transporting and using the material, and what happens at the end of its life. It is measured in kilograms of carbon dioxide emitted (KgCO2) per unit of material (eg. kgCO2/kg). The convention of carbon dioxide equivalent (CO2e) is used to include all greenhouse gasses, eg. methane, nitrous oxides and ozone converted into units of CO2.

Why is embodied carbon important?

• As a measure of greenhouse gas emissions it is directly correlated to global warming and therefore a major cause of climate change.

• Embodied carbon in construction is a significant proportion of global emissions. According to the World Green Building Council, construction accounts for 11% of total global carbon emissions.1

• It is widely acknowledged that the next twenty years are critical in limiting global temperature increases below the 1.5oC target ratified by 197 countries in the 2015 Paris agreement.2 Representing the up-front carbon emissions of buildings, embodied carbon must be minimised to achieve the rapid reductions required today.3

• Embodied Carbon is likely to become a regulated in the UK. The Netherlands, France, Finland and California already have embodied carbon assessment as a condition of certain planning approval.4 It is a requirement in prominent environmental certification schemes such as BREEAM or LEED, and only a matter of time before it is incorporated in to UK building regulations.

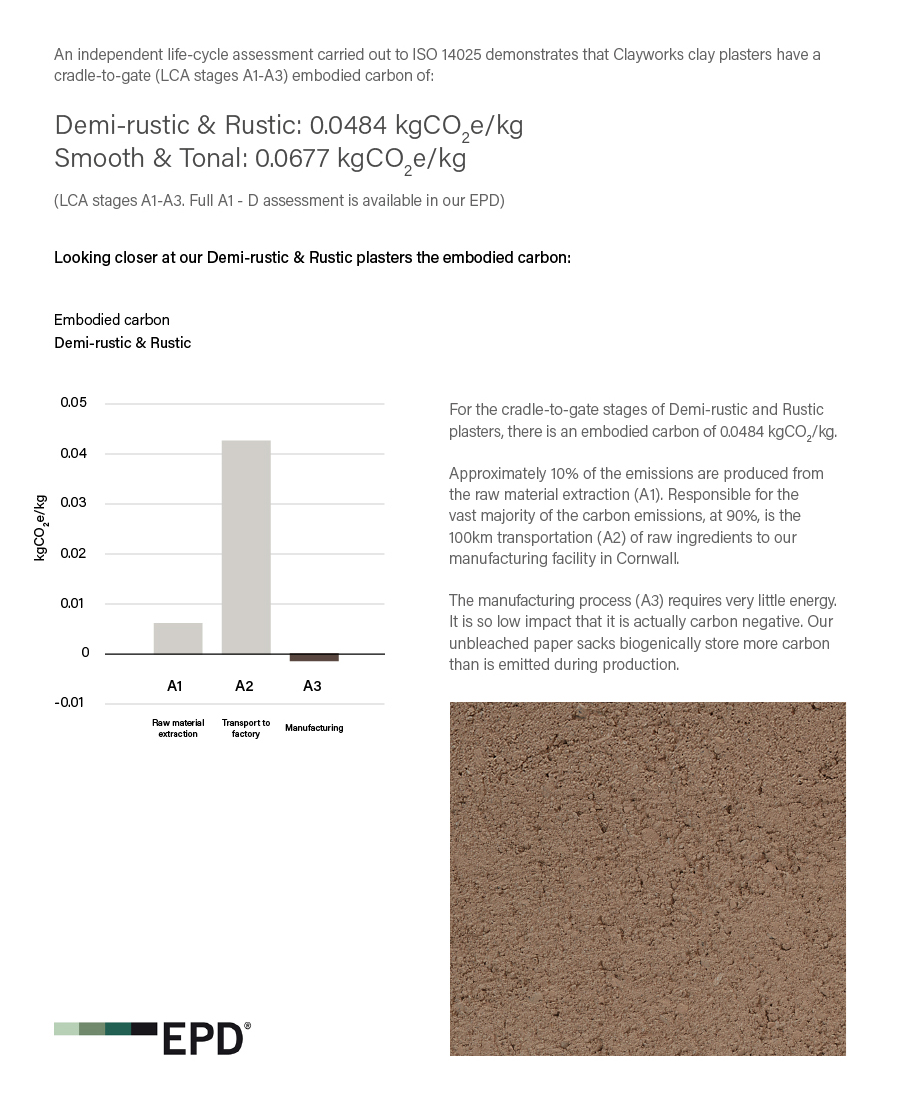

5. EMBODIED CARBON OF CLAYWORKS CLAY PLASTERS

6. END OF LIFE SCENARIO

Clayworks clay plasters are both reusable and biodegradable, and no special equipment or facilities are needed for their disposal (C4) or reprocessing (D). The life cycle assessment found that disposal results in an insignificant amount of carbon (0.002 kgCO2e/kg). Better yet, if reused our clay plaster was found to have a carbon negative value (-0.01 kgCO2e/kg).

7. HOW DO CLAY PLASTERS COMPARE

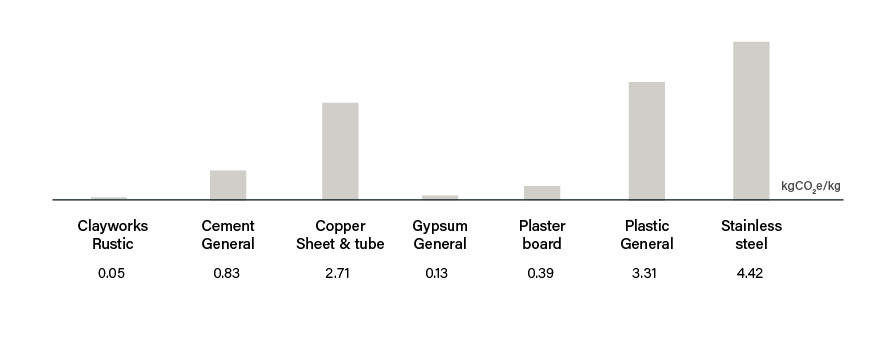

Providing a sense of scale, the chart below shows Clayworks Rustic clay plaster’s embodied carbon in comparison with other common building materials. The values here are taken from the Inventory of Carbon and Energy (ICE),5 an open source database of embodied carbon and energy measurements.

This graph demonstrates how clay plaster compares kilogram-for-kilogram with other materials. However, these values are not reflective of how we use materials in architecture and interiors. For example, we don’t specify ceramics by the kg.

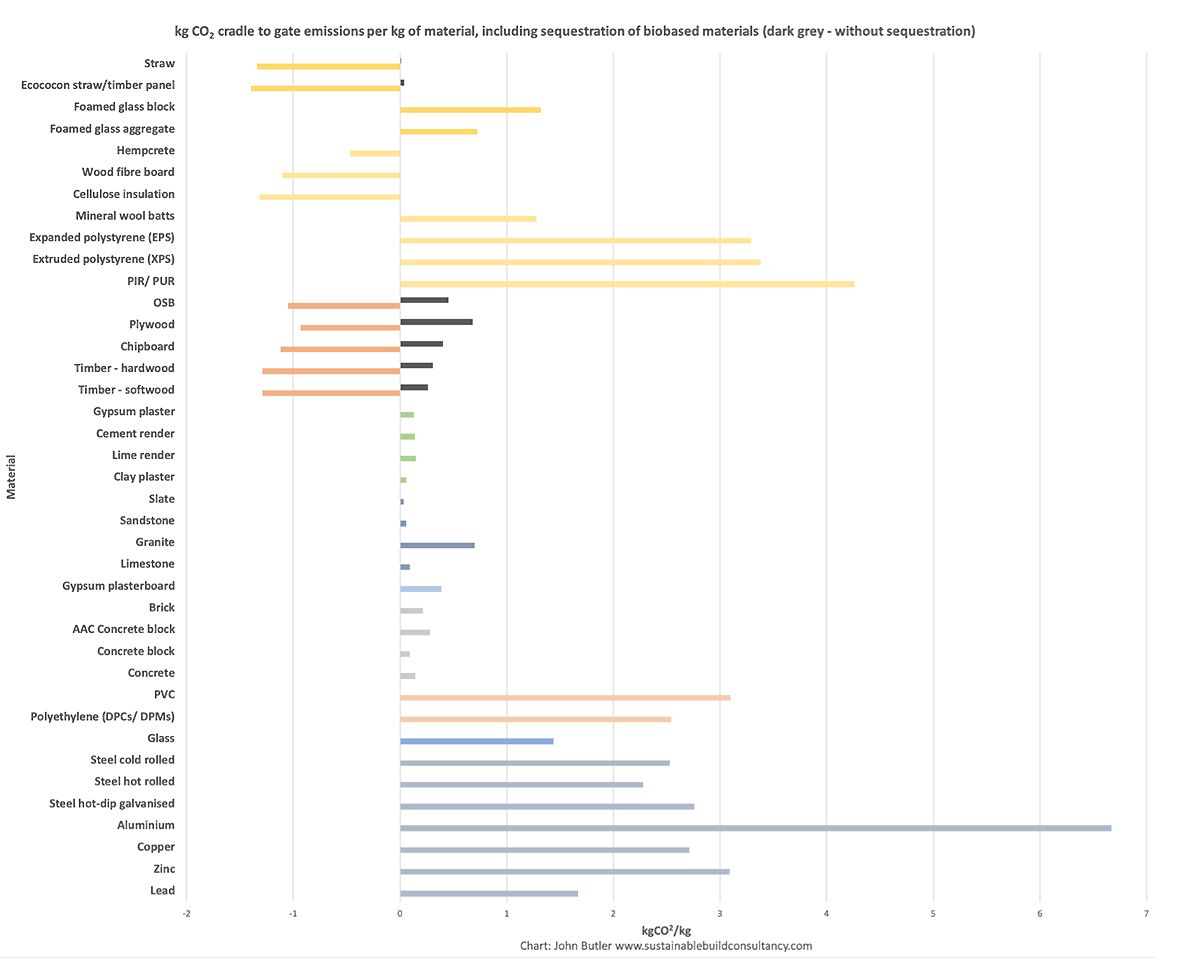

Providing a sense of scale, the chart below shows Clayworks clay plaster’s embodied carbon in comparison with other common building materials. The chart is produced by John Butler Sustainable Building Consultancy using values taken from the Inventory and Carbon and Energy5 (ICE) and EPD data.

To provide a more accurate picture of the relative embodied carbon of products in practice, we must compare them in the units they are used, typically per m2 at a defined thickness. This concept is known as ‘functional units’.

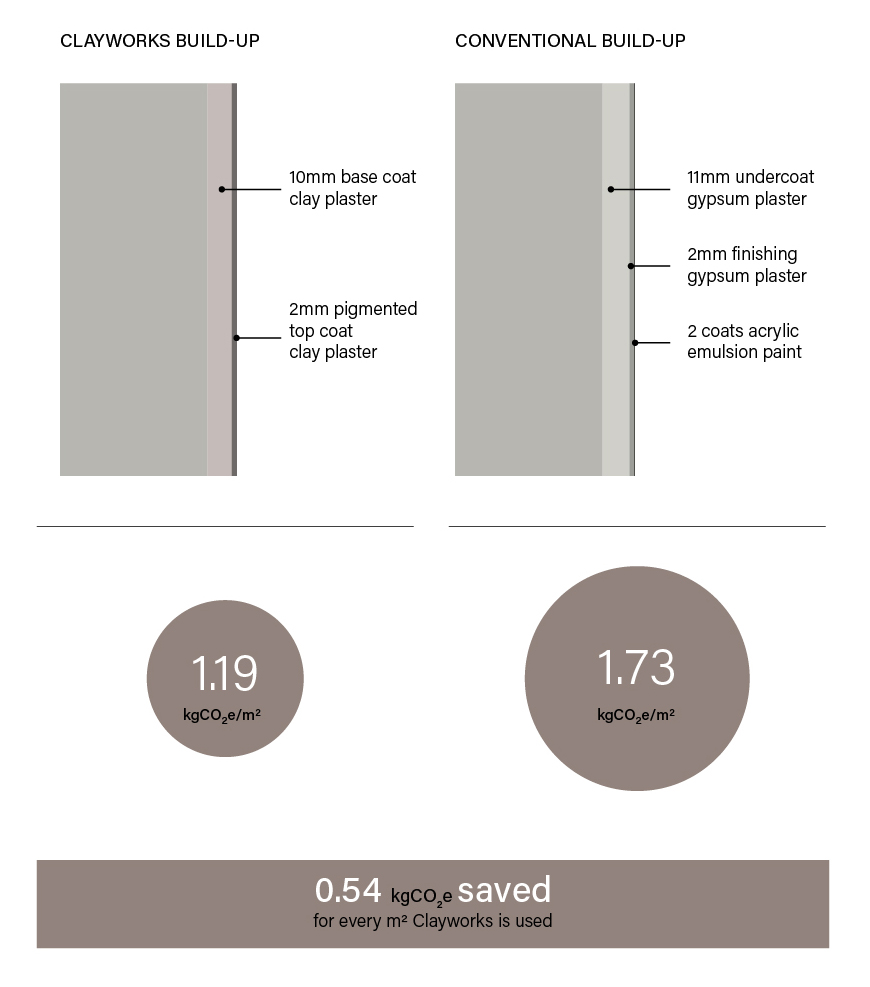

8. INTERIOR WALL FINISH COMPARISON

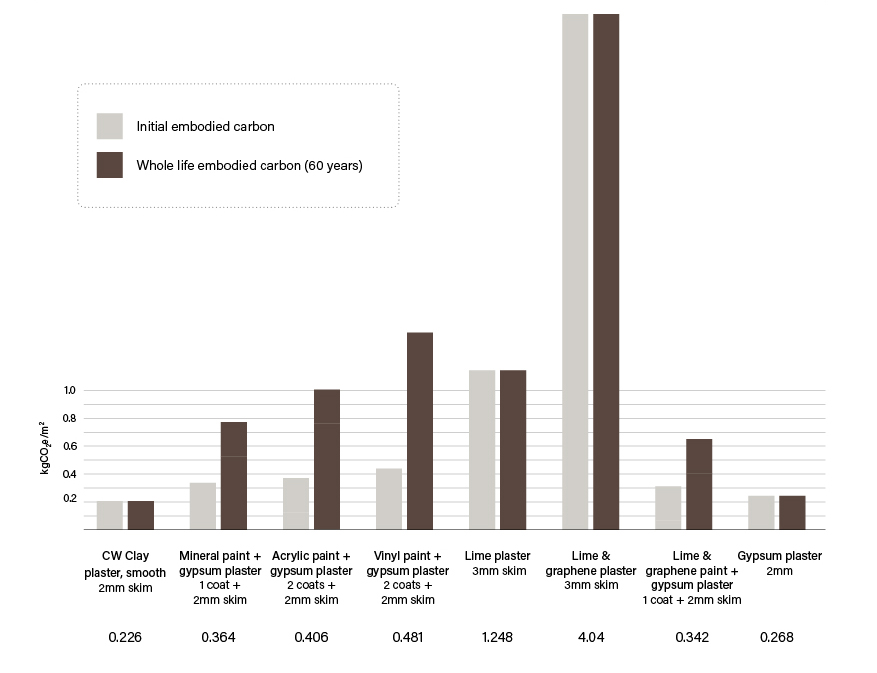

The graph above shows the embodied carbon of interior wall finishes per square meter at their typical thickness (functional units). The values are all taken from product EPDs calculated to ISO 14025. The light bar represents the initial embodied carbon, the emissions associated with the first application. The dark bar represents the embodied carbon for a whole building’s life of 60 years, accounting for the expected required reapplications over this period. For example, paint has an expected lifespan of 10 years, requiring 6x applications over a 60 year building life.

Looking at the initial embodied carbon values clay plaster compares favourably, sitting at the lower end of the scale. However paints across the board have the lowest embodied carbon due to the tiny quantities of material used in their application, a paint coat is on average 0.1mm thick, compared to a 2-3mm plaster coat.

This advantage is quickly lost when considered over a building’s lifespan. With paint’s need for repeated reapplication, clay plasters offer a lower whole life embodied carbon. This demonstrates the importance of designing for longevity as a sustainable design strategy.

9. CLAY PLASTER AND PAINTED GYPSUM PLASTER COMPARISON

10. CLAY PLASTER AND CIRCULAR DESIGN

The planet is finite. It is a closed system and we are consuming its material resources at an alarming rate.

With the Earth’s population set to increase by a further 2 billion people by 2050 our consumption will only continue to increase, unless we change the systems of manufacturing and consumption.

The ‘circular economy’ is such a change that offers a model for a more sustainable use of resources. It is a shift away from the current model of ‘take-make-waste’ to one of ‘take-make-make again’. When perfectly applied, non-renewable materials are designed for perpetual recycling and biological materials are used at a rate they can be endlessly replenished.

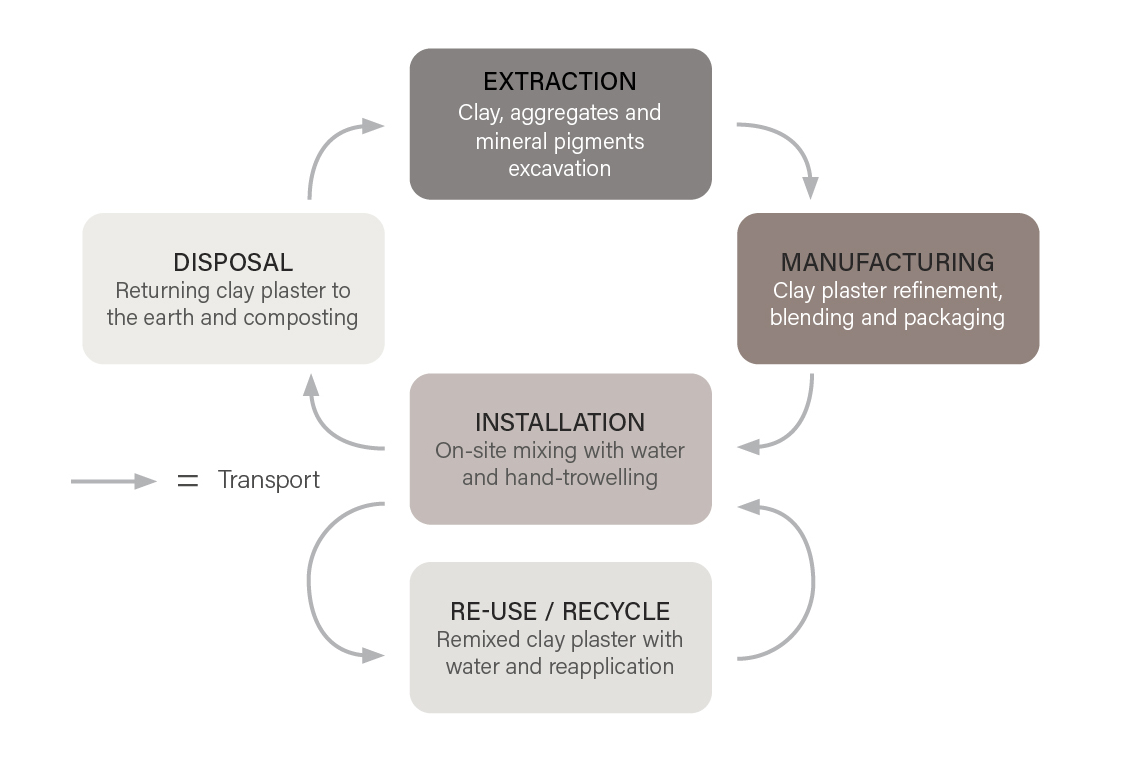

There are three key ideas within circular design principles, and clay plasters tick each of these boxes.

Use materials that are abundant or renewable

Made of earthen materials, clay is incredibly abundant and available all over the world.

Use materials that can be recycled, reused or returned to natural systems without depletion

At the end of its service life, clay plaster can be recycled and reused again through a simple low energy process.

If disposal is necessary, clay plaster is non-toxic and biodegradable. It can be readily returned to the earth and even composted. There is negligible waste in Clayworks production. The majority of our Finishes are pigmented with natural, organic pigments. However, some colours contain chemical pigments – please contact us for further advice. Glazes and Primers may contain synthetics or chemicals.

Design for longevity

Clay plaster requires little maintenance, is UV stable and won’t degrade over time. Any damage that does occur can be easily repaired on site. Due to these properties, clay plaster has an expected lifespan of 60 years and can last the entire life of buildings.

11. CLAYWORKS CLAY PLASTERS LIFE CYCLE

12. CLAY PLASTERS, HEALTH AND WELLBEING

At Clayworks we take a holistic approach to sustainability, considering not only the environmental aspects of production, but also considering the social impacts of our products. One of the most important social aspects to consider is the health and wellbeing of building occupants.

It is proven that humans are effected by the quality of their environment. We spend up-to 90% of our time indoors within the micro-environments we create. The materials used within these environments impact our physical and mental health. It is imperative that we design interiors that do not harm us, or better yet, that allow us to flourish.

Clayworks clay plasters are completely inert. They are non-toxic and release low Volatile Organic Compounds (VOCs) in their production or when employed within an interior.

Their moisture buffering properties help maintain a comfortable level of humidity for occupants, while reducing the chance of mould or mildew formation within interiors.

This topic is explored in greater detail in our Health and Wellbeing document.

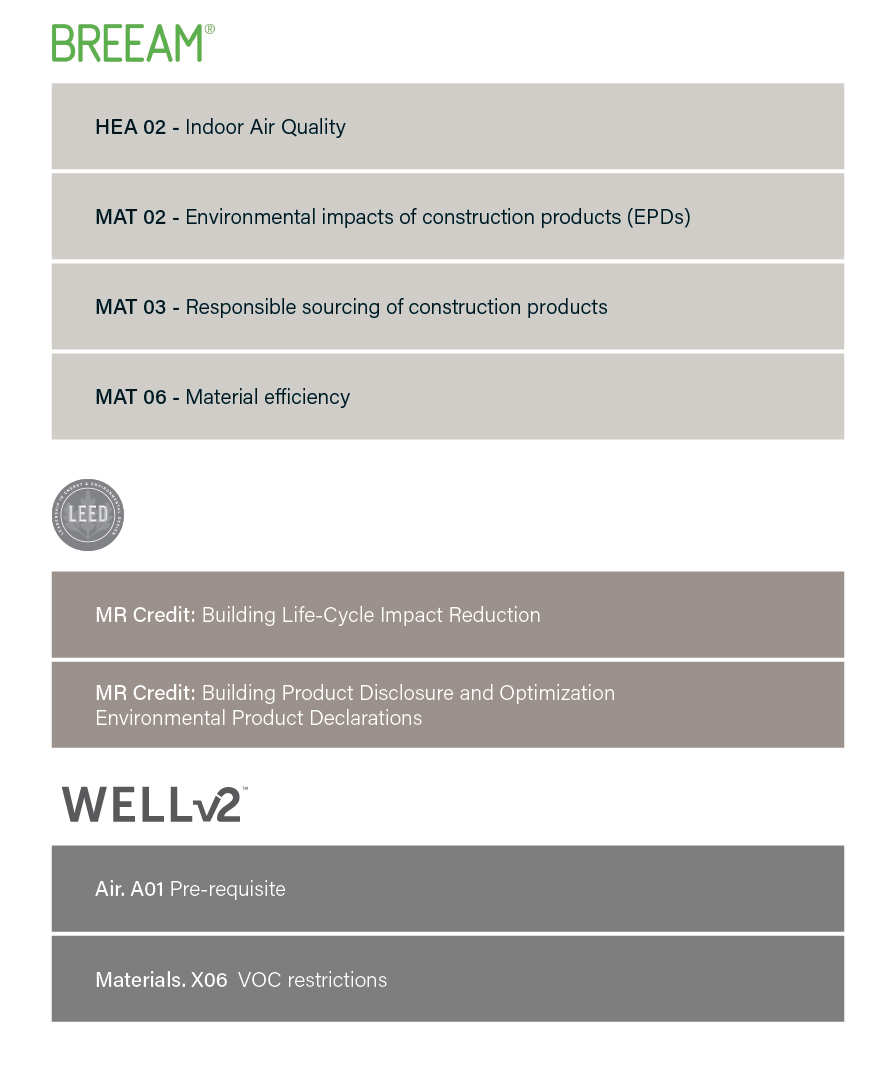

13. CLAYWORKS AND RATING SYSTEMS

Clayworks clay plasters meet the criteria of, and therefore can contribute to achieving the following environmental rating system credits.

14. SOURCES

1. World Green Building Council – “Advancing Net Zero embodied carbon call to action report” (2019).

2. United Nations Framework Convention on Climate Change – https://unfccc.int/process-and-meetings/the-paris-agreement /the-paris-agreement.

3. Committee on Climate Change (2020) “Reducing UK emissions Progress Report to Parliament”.

Aecom, for the Committee on Climate Change, (2019) “Options for incorporating embodied and sequestered carbon into the building standards framework”.

World Green Building Council (2019) “Bringing embodied carbon upfront”.

Bernadino D’Amico, Francesco Pomponi, Jim Hart & JannikGiesekam,forZeroWasteScotland,(2020)

“Embodied Carbon. Status Quo & Suggested Roadmap”.

Kate Scott, Katy Roelich, Anne Owen & John Barrett (2018) “Extending European energy efficiency

standards to include material use: an analysis” Climate Policy, 18:5, 627-641.

4. Architects Climate Action Network (ACAN) – “The Carbon Footprint of Construction. The case for regulating embodied carbon in construction to significantly address the impact of the industry on the climate.” (February 2021).

5. Circular Ecology – “Inventory of Carbon and Energy (ICE) v2”.

6. UN world population prospects – https://www.un.org/development/desa/en/news/population/world-population-prospects-2019.html

7. Ellen Macarthur Foundation – “What is the circular economy” – https://www.ellenmacarthurfoundation.org/circular-economy/what-is-the-circular-economy

8. John Butler. Sustainable Build Consultancy 2020.

Interior wall finish product comparison sources

Clay plaster – Clayworks Demi-rustic, Rustic, Smooth & Tonal clay plasters. EPD registration number: S-P-02278.

Mineral paint – AIRLITE paints: Sunlight and Purelight. EPD registration number: S-P-01326.

Acrylic emulsion paint – Dulux Trade Supermatt – EPD registration number: 00000568.

Vinyl emulsion paint – Dulux Trade Vinyl Matt – EPD registration number: 00000546.

Lime plaster – VDPM Bauprocalc 830 – Hydraulic lime plaster – EPD registration number: EPDIWM20190153IBG1DE.

Lime plaster with graphene reinforcement – Graphenestone mortar – Earth collection – EPD registration number: S-P-01618.

Lime paint with graphene reinforcement – Graphenestone – Ecosphere Interior paint – EPD registration number: S-P-01050.

Gypsum plaster – Gyproc Finish Plaster (Skimcoat, Skimcoat Short Set, Carlite and Carlite Ultra products) – EPD registration number: S-P-00584.

Gypsum undercoat plaster – Thistle ToughCoat and Thistle HardWall – British Gypsum – EPD registration number: S-P-00609.