Design Details

DESIGN DETAILS – TECHNICAL GUIDANCE – LIMITATIONS

We strongly recommend that our products are installed by Clayworks Approved Plasterers.

TECHNICAL GUIDANCE

• These guidelines are for design and construction planning purposes only.

• Approved Plasterer to check suitability of substrates and advise regarding required preparation.

• Substrates to be structurally sound and solid to prevent movement. Thicker finishes require reinforced substrates – please see Design Details below. Substrates to be dry.

• Non-flat and curved substrates may require different substrate preparation – please enquire.

• All beads, trims, mesh etc. to be specified and supplied by Approved Plasterer. Larger gauge trims & beads may be required for thicker finishes – Approved Plasterer to advise.

• For clay plasters: all beads and trims to be set in with gypsum plaster or bonding agent. All beads and trims to be primed with Clayworks primer prior to application of Clayworks clay plasters.

• We recommend using surface mounted corner trims in highly trafficked areas. For thicker finishes, we advise rounded corners as they provide increased durability.

• Handrails are recommended to prevent build-up of dirt from hands.

LIMITATIONS

• Clayworks products are not suitable for doors, floors, stair treads, worktops, seating and other horizontal surfaces that are subject to loads.

• Clayworks clay plasters are well suited to bathrooms, kitchens and rooms with occasional high humidity. However they are not suitable for wet areas with direct water contact (e.g. shower enclosure or behind a sink without a splash-back). See Clayworks Tadelakt finish where a water resistant finish is required.

• Please consult with us to check suitability for commercial WCs and bathrooms etc. where more frequent and intense cleaning is expected.

• Timber, including MDF & plywood, are not suitable substrates for Clayworks products.

• Clayworks clay plasters are for interior use only. See Clayworks Exterior finish for exterior applications.

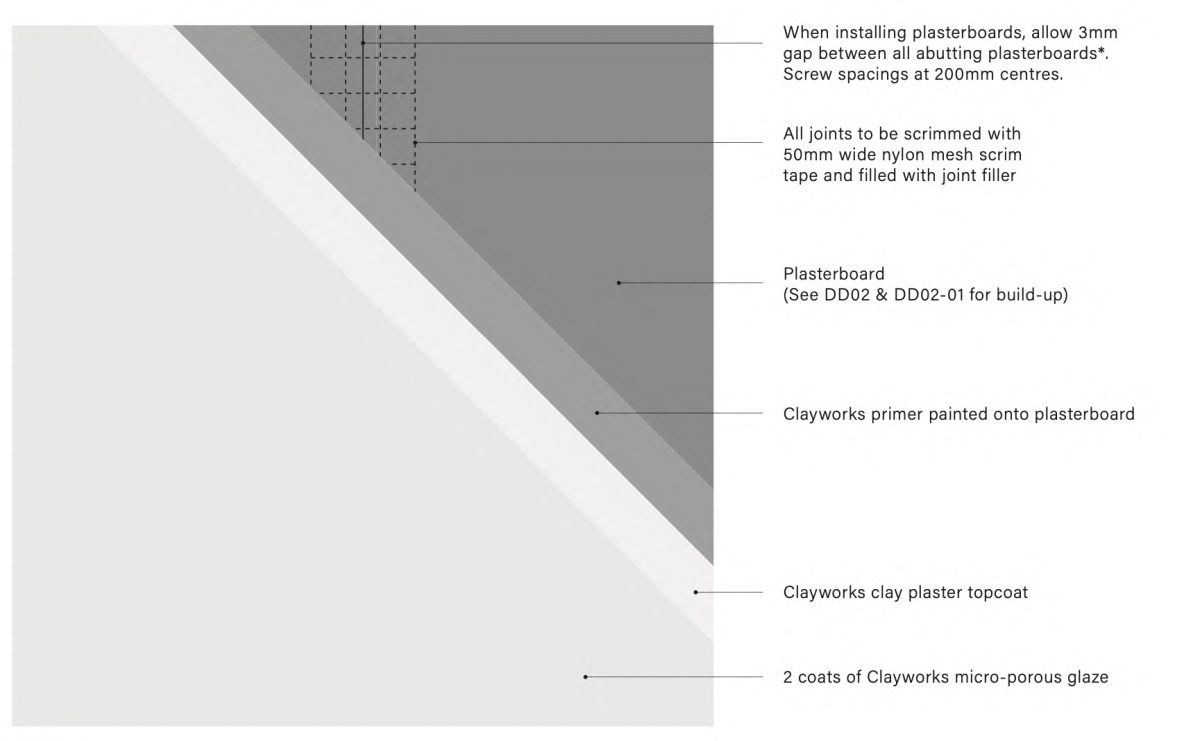

DD01 - PLASTERBOARD JOINT DETAIL FOR INTERIOR CLAYWORKS CLAY PLASTER FINISHES

Notes

*Alternatively to 3 mm gaps, a gypsum skim can be applied to the whole surface prior to the Clayworks primer. All screws to be filled with joint filler. All internal corners to be scrimmed with mesh tape – do not use paper tape for jointing as it can de-laminate.

Approved Plasterer to check suitability of substrates and advise regarding required preparation. Approved Plasterer to confirm build-up and specifications.

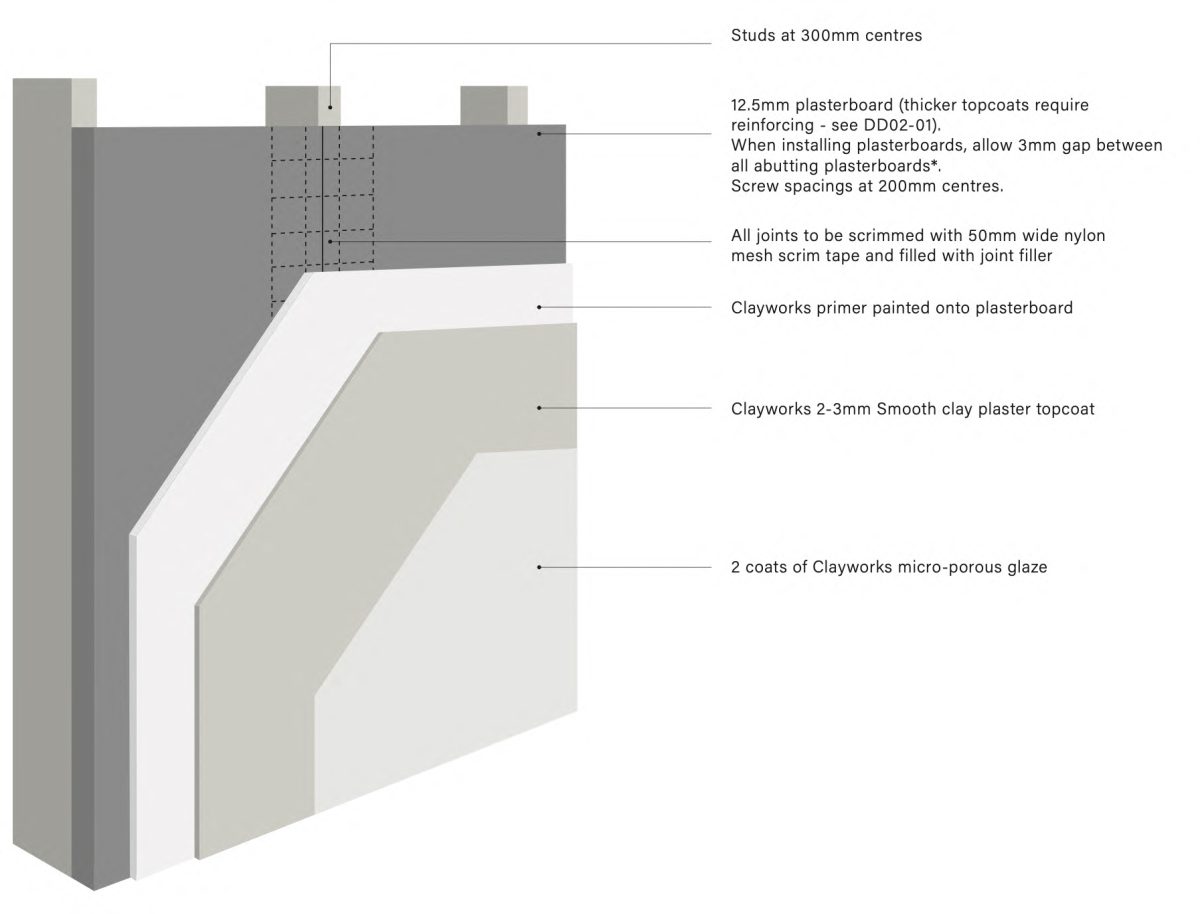

DD02 - PLASTERBOARD SUBSTRATE: FOR SMOOTH & SMOOTH TONAL INTERIOR CLAY PLASTER FINISHES

Notes

* Alternatively to 3mm gaps, a gypsum skim can be applied to the whole surface prior to the Clayworks primer. All screws to be filled with joint filler. All internal corners to be scrimmed with mesh tape – do not use paper tape for jointing as it can de-laminate.

Approved Plasterer to check suitability of substrates and advise regarding required preparation. Approved Plasterer to confirm build-up and specifications.

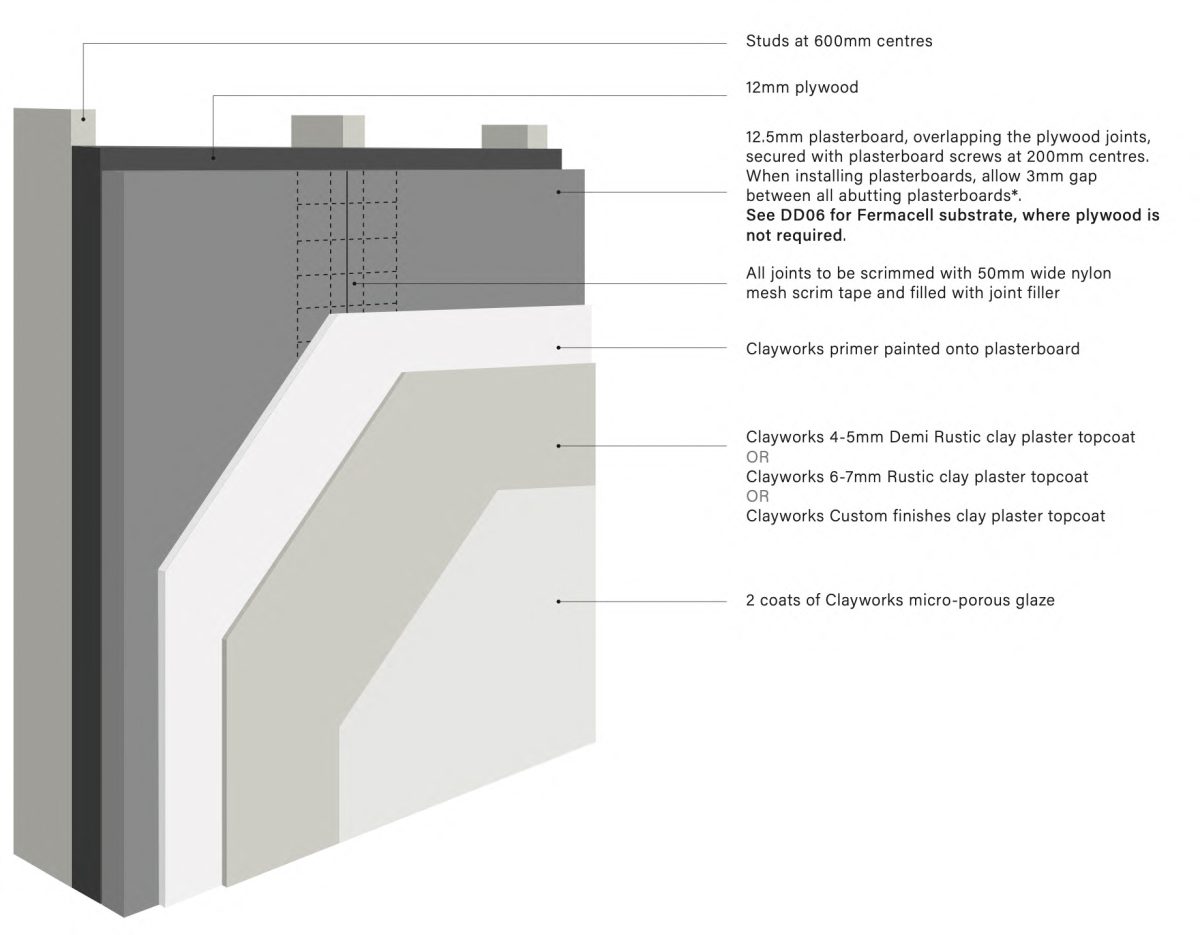

DD02-01 - PLASTERBOARD SUBSTRATE: FOR DEMI RUSTIC, RUSTIC & CUSTOM INTERIOR CLAY PLASTER FINISHES

Notes

See DD06 for Fermacell substrate, where plywood is not required.

* Alternatively to 3mm gaps, a gypsum skim can be applied to the whole surface prior to the Clayworks primer. All screws to be filled with joint filler.

All internal corners to be scrimmed with mesh tape – do not use paper tape for jointing as it can de-laminate.

Larger gauge trims & beads may be required for thicker finishes – Approved Plasterer to advise.

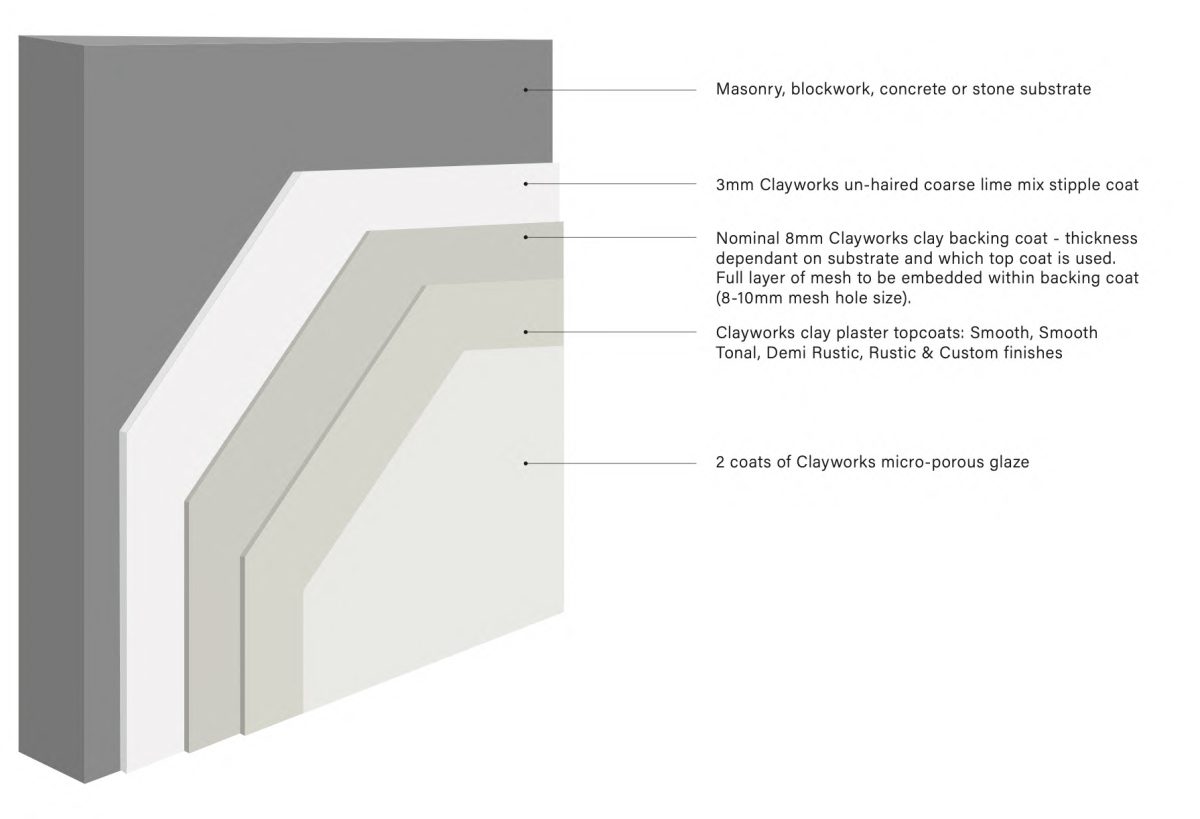

DD03 - MASONRY, BLOCKWORK, CONCRETE & STONE SUBSTRATE: FOR INTERIOR CLAY PLASTER FINISHES

Notes

Backing coat: Approved Plasterer to assess substrate and advise what thickness of backing coat is required.

Larger gauge trims & beads may be required for thicker finishes – Approved Plasterer to advise.

Approved Plasterer to check suitability of substrates and advise regarding required preparation. Approved Plasterer to confirm build-up and specifications.

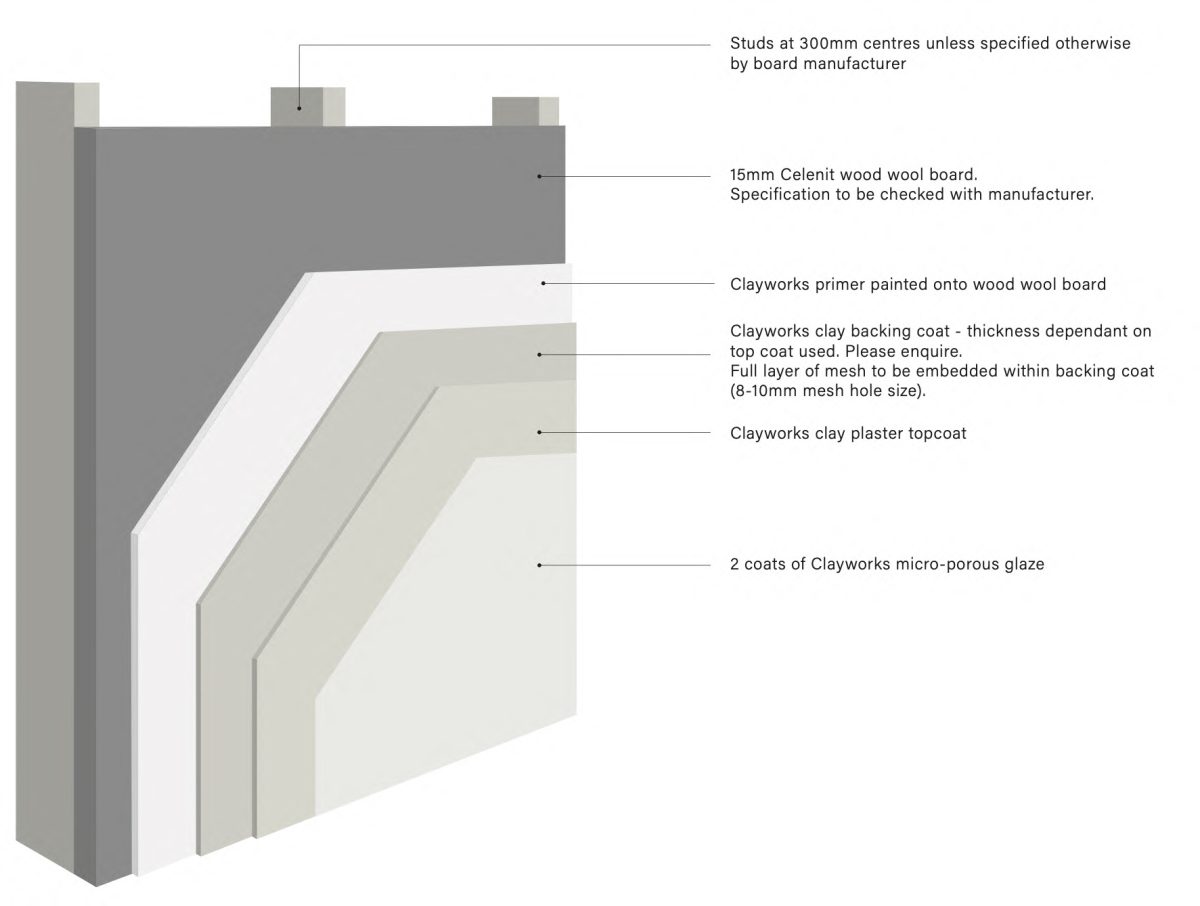

DD04 - WOOD FIBRE INSULATION BOARD OR CORK INSULATION BOARD SUBSTRATES: FOR INTERIOR CLAY PLASTER FINISHES

Notes

All internal corners to be scrimmed with mesh tape – do not use paper tape for jointing as it can de-laminate.

Larger gauge trims & beads may be required for thicker finishes – Approved Plasterer to advise.

Approved Plasterer to check suitability of substrates and advise regarding required preparation. Approved Plasterer to confirm build-up and specifications.

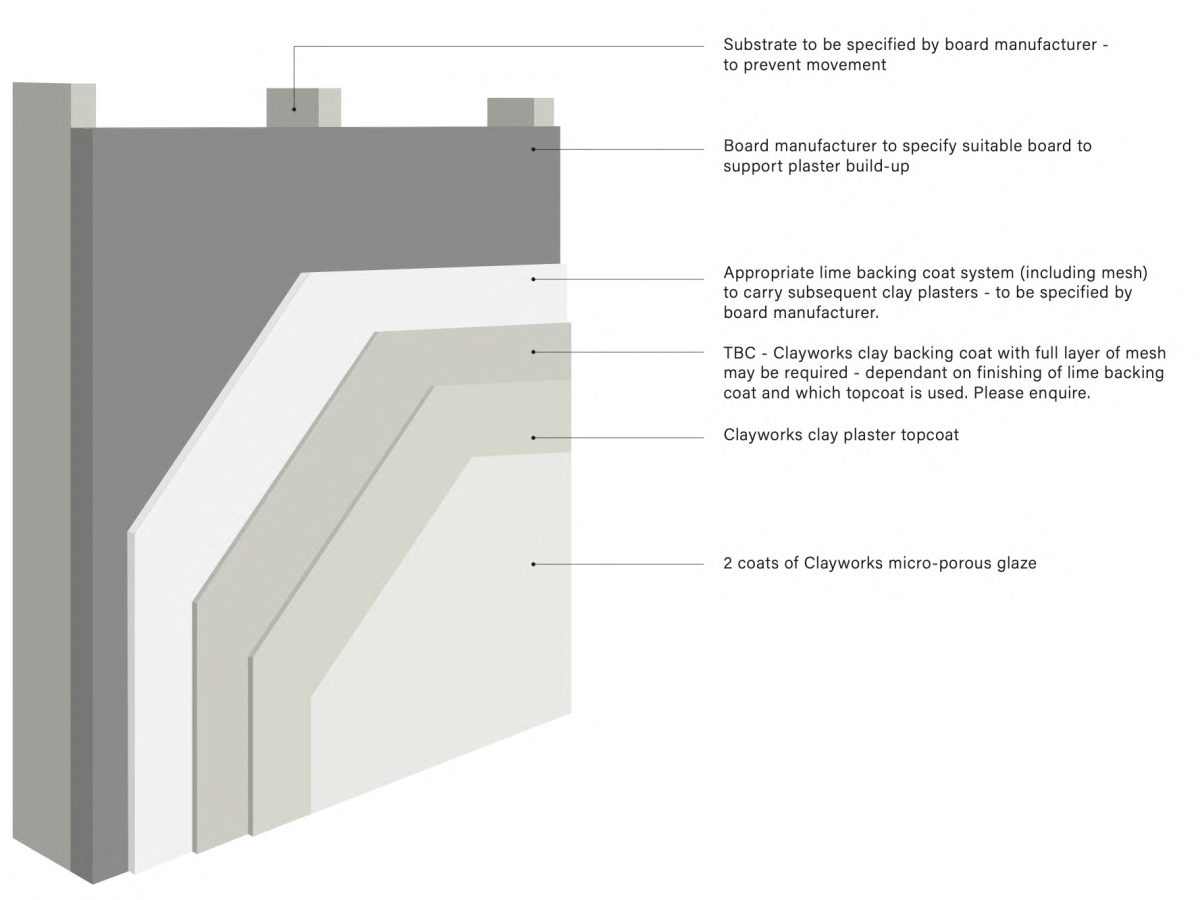

DD05 - WOOD WOOL PLASTER CARRIER BOARD SUBSTRATE: FOR INTERIOR CLAY PLASTER FINISHES

Notes

All internal corners to be scrimmed with mesh tape – do not use paper tape for jointing as it can de-laminate.

Larger gauge trims & beads may be required for thicker finishes – Approved Plasterer to advise.

Approved Plasterer to check suitability of substrates and advise regarding required preparation. Approved Plasterer to confirm build-up and specifications.

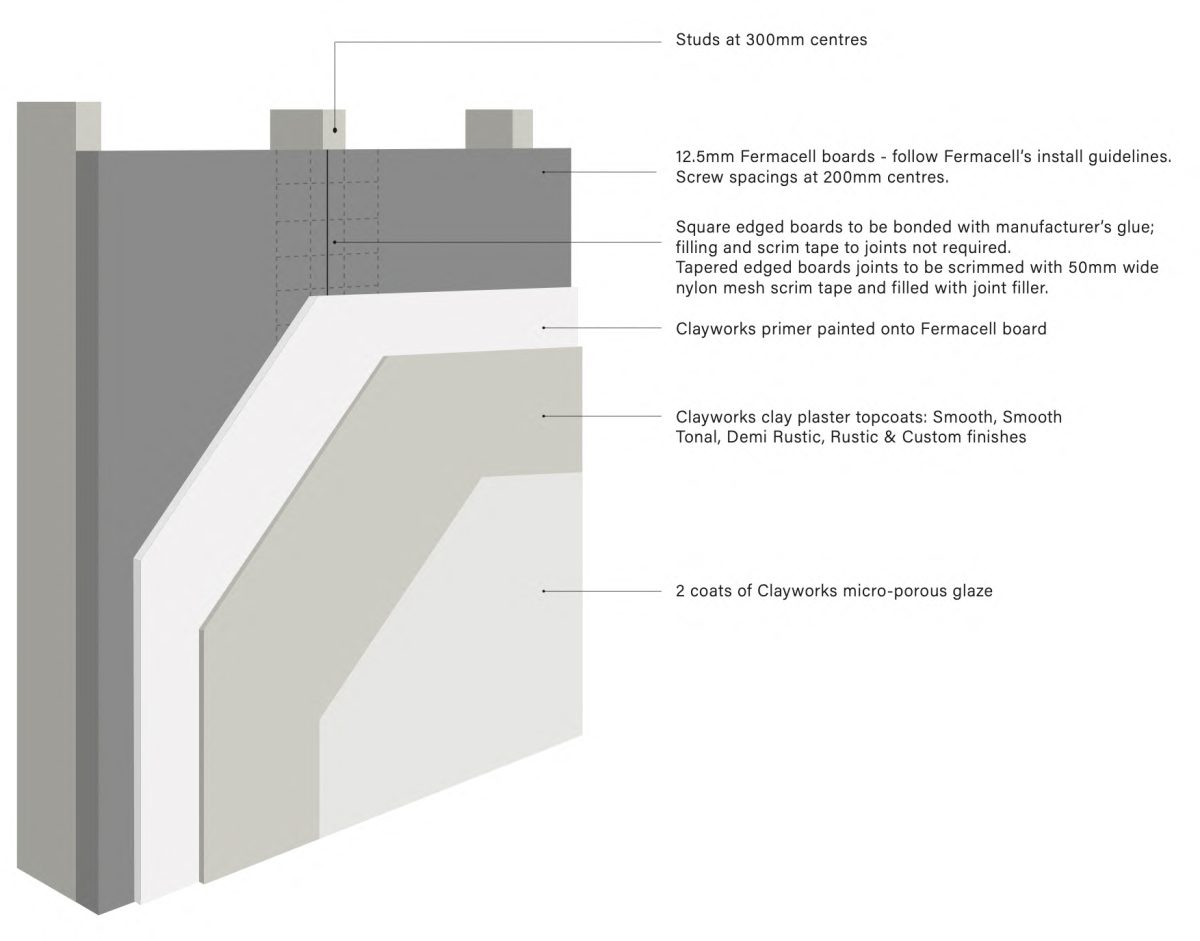

DD06 - FERMACELL BOARD SUBSTRATE: FOR INTERIOR CLAY PLASTER FINISHES

Notes

All screws to be filled with joint filler.

Follow Fermacell guidelines for internal corners.

Larger gauge trims & beads may be required for thicker finishes – Approved Plasterer to advise.

Approved Plasterer to check suitability of substrates and advise regarding required preparation. Approved Plasterer to confirm build-up and specifications.

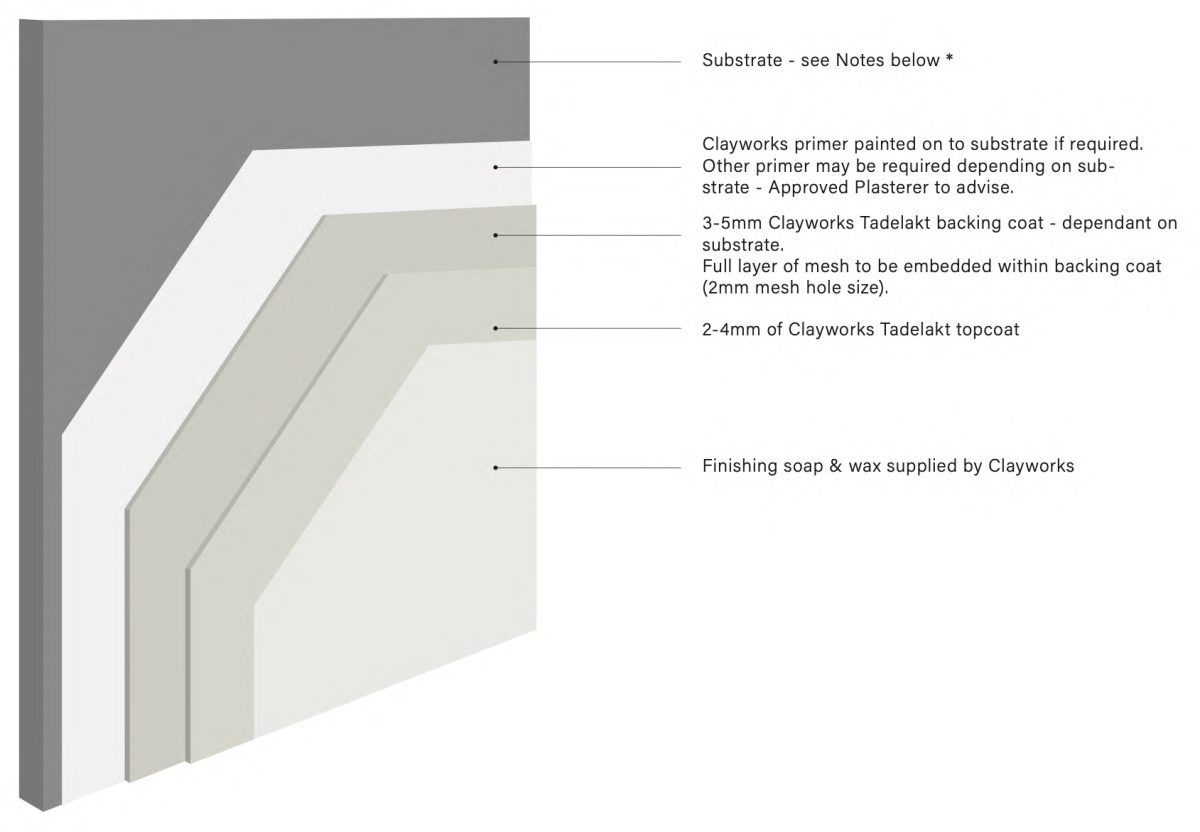

DD20 - BUILD-UP FOR: CLAYWORKS TADELAKT INTERIOR FINISH

Notes:

* SUBSTRATES

Plasterboard: (moisture resistant plasterboard to be specified). Plasterboard joints to be taped and filled. Plasterboard to have 12 mm plywood backing behind. Stud wall behind to have studs at 300 mm centres.

Fermacell:

check with manufacturer for suitable specification. Stud wall behind to have studs at 300 mm centres.

Tile backing boards:

to receive Stonefix or similar backing coat system with mesh embedded. Check with board manufacturer and Approved Plasterer for suitable specification.

Blockwork, masonry and other substrates:

consult with Approved Plasterer.

Approved Plasterer to check suitability of substrates and advise regarding required preparation.

Approved Plasterer to confirm build-up and specifications.

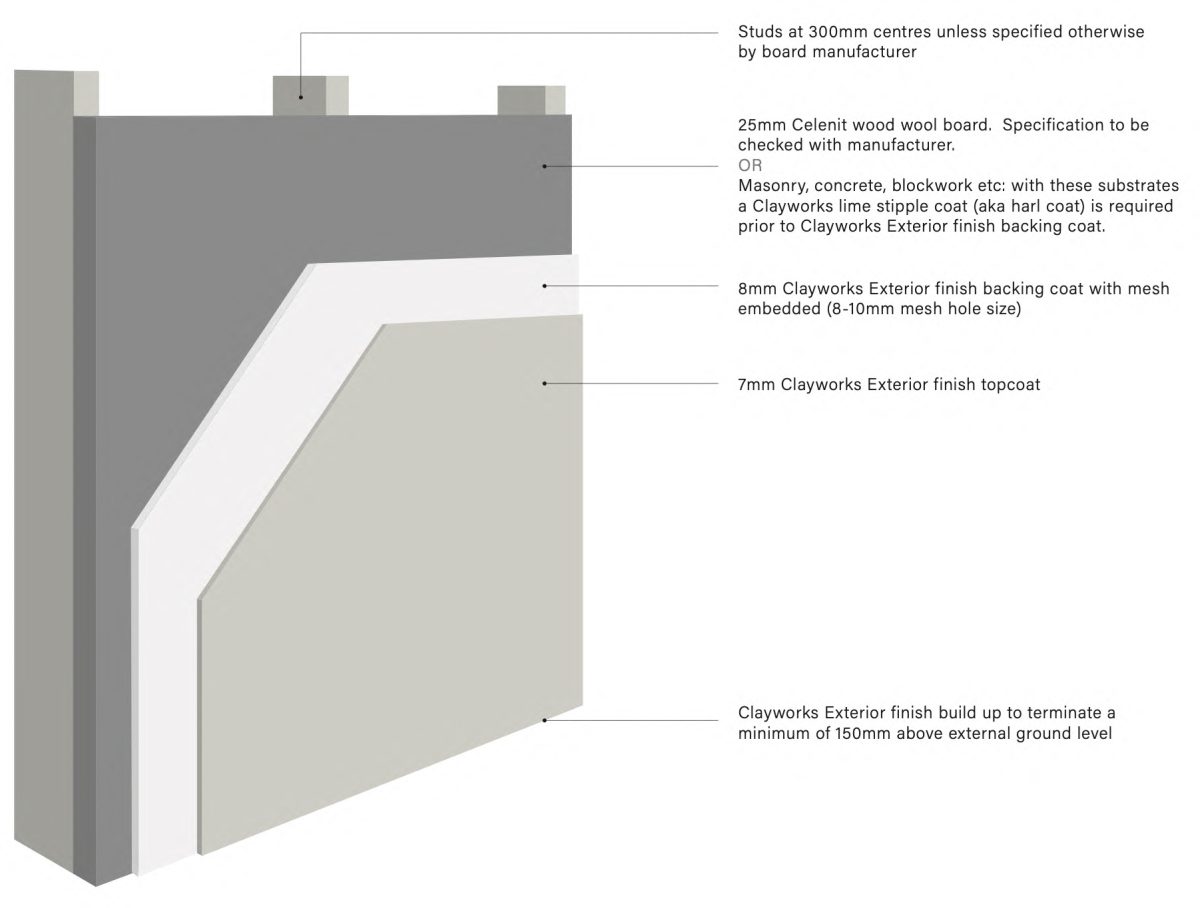

DD30 - BUILD-UP: FOR CLAYWORKS EXTERIOR FINISH

Notes

Design considerations

• roof overhang or capping should be included to protect the finish at the top of wall.

• cills should not be formed with Clayworks Exterior finish.

Approved Plasterer to check suitability of substrates and advise regarding required preparation.

Approved Plasterer to confirm build-up and specifications.

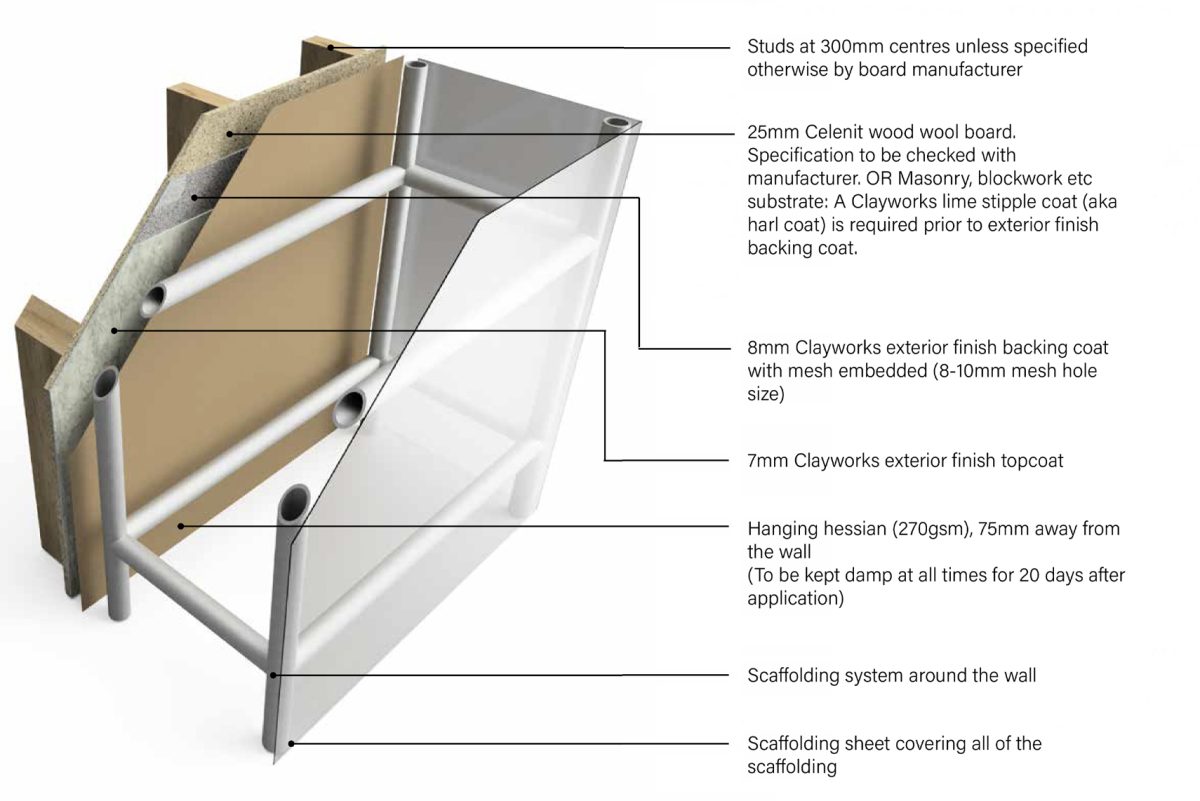

DD-30-01 - EXTERIOR MATERIALS CURING REQUIREMENTS

Notes

No direct sunlight to hit the hessian under sheets.

Regular baffles to prevent wind tunnel effect.

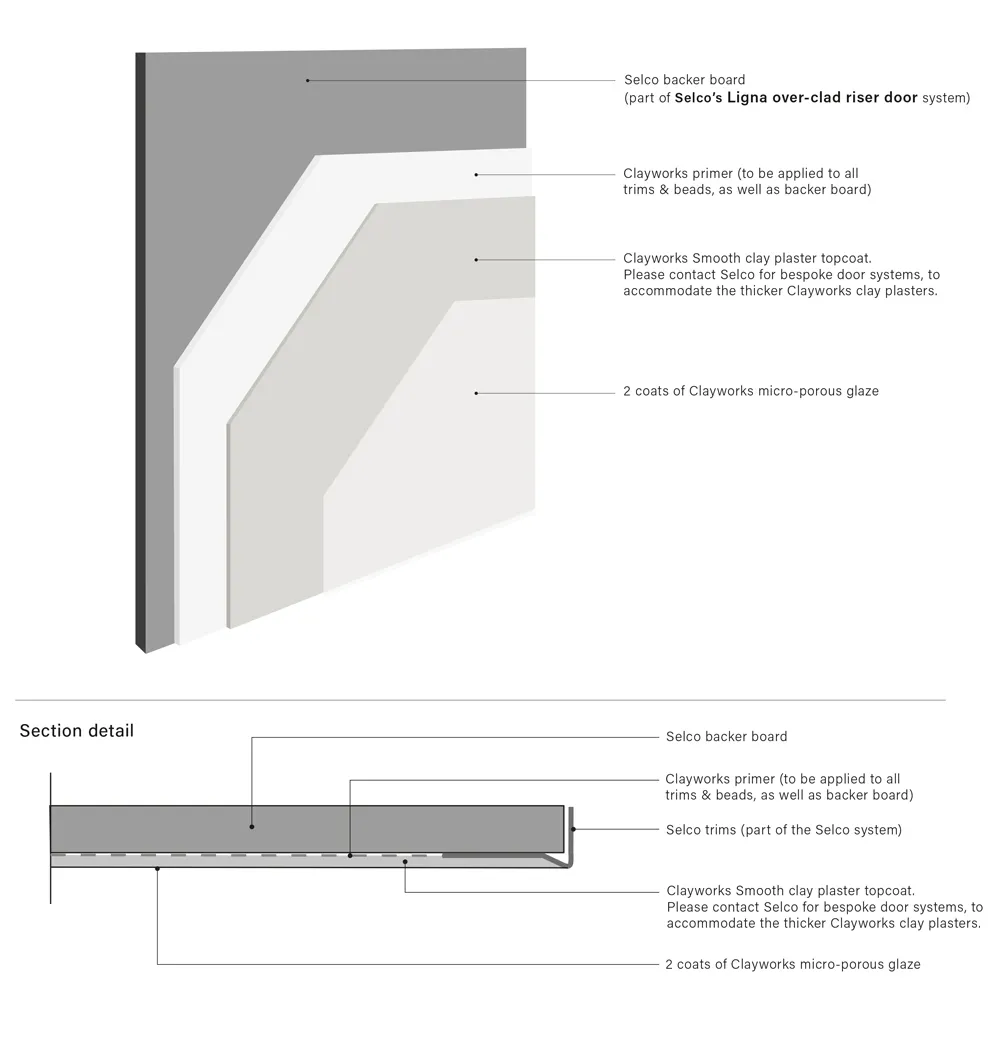

DD40 - BUILD-UP FOR CLAYWORKS CLAY PLASTERS ON ACCESS / RISER DOORS

Notes

We recommenced using the Ligna over-clad riser door.

The above details are not to scale.